Active Principles of Low-Energy, Intelligent Production Systems

Sub-Projects

The majority of the energy used by cutting machine tools connected to the main power supply is consumed in auxiliary systems. The proportion of the energy consumption attributed to machining is generally low. Auxiliary units in production systems contribute significantly to the total energy consumption of a production system. To date, there is no known holistic method for calculating the overall energy requirement which, alongside energy consumers such as the main and secondary drive systems, also takes account of auxiliary units as well as hydraulic, pneumatic and kinetic energy. Alongside energy utilisation on account of the optimised efficiency of the production system, in future the use of energy cycles (energy recovery) is set to increase in significance. Ensuring the energy-efficient open-loop and closed-loop control of electromechanical axes is another focus of the research.

- Energy-economy accounting of machine tools

- Reduction of the energy requirement of production systems in operation

- Networking and management of decentralised, stationary energy storage devices

- Controlled system identification in ongoing operation

- Requirement-based operation of machine tool components and the requirement-based control of auxiliary units

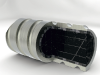

More energy-efficient core components make a con¬siderable contribution to reducing the overall energy requirement of machine tools, as a result of which they are an important research topic.

Within the field of action, the specific points of focus are the development of lightweight components, the development of components with minimal thermal expansion in order to reduce cooling cost, the establishment of energy harvesting and recuperation and the development of self-sufficient adaptronic components.

Heads of the Field of Action

Prof. Reimund Neugebauer

President of the Fraunhofer-Gesellschaftphone: +49 (0)89 1205-1000

fax: +49 (0)89 1205-771000

President of the Fraunhofer-Gesellschaft

Prof. Welf-Guntram Drossel

Professorship for Machine Tools and Forming Technologyphone: +49 (0)371 531-23500

fax: +49 (0)371 531-23509

e-mail: wzm@tu-chemnitz.de

Professorship for Machine Tools and Forming Technology

Participants

| Prof. Reimund Neugebauer | President of the Fraunhofer-Gesellschaft |

| Prof. Welf-Guntram Drossel | Professorship for Machine Tools and Forming Technology |

| Dr. Volker Wittstock | Professorship for Machine Tools and Forming Technology |

| Prof. Lothar Kroll | Professorship for Lightweight Structures and Polymer Technology |

| Prof. Bernhard Wielage | Professorship of Composite Materials (German) |

| Prof. Klaus Nendel | Professorship of Materials Handling and Conveying Engineering (German) |

| Prof. Uwe Götze | Professorship Management Accounting and Controlling |

| Prof. Frank Richter | Professorship Solid Body Physics (German) |