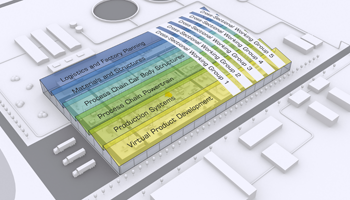

Cross-Sectional Working Groups

The task of the CWGs was to initiate and support interdisciplinary subjects located at the interfaces between the fields of action. Working in interdisciplinary teams, the scientists developed new active principles, construction methods and technologies for the reduction of the primary energy requirement and for increasing energy efficiency in production.

Research Tasks of the Cross-Sectional Working Groups

- Conducting interdisciplinary accounting and evaluation of eniPROD® objects

- Development of cross-sectoral methods

- Exchange and transfer of acquired knowledge

- Development of energy monitoring and management methods

- Preparation of energy information and knowledge

- Design of an energy management system

- Use of aFEM for variant calculation of a fibre-reinforced conveyor chain link

- Testing and optimisation of the geometry parameters with rapid variant calculation and parameter variation

- Combination of various material models of complex component assemblies

- Development of simulation-based energy conservation concepts for the cooling units of machine tools

- Performance of studies on thermal treatment in forming

- Use of thin layers for the reduction of friction

- Financial accounting of press hardening process chains

- Development and implementation of a technology demonstrator within composite materials

- Visualisation of the process chain car body structures using Virtual Reality

Heads of the Cross-Sectional Working Groups (CWG)

CWG1:

Prof. Uwe Götze

Professorship Management Accounting and Controllingphone: +49 (0)371 531 26160

fax: +49 (0)371 531-26169

e-mail: uwe.goetze@wirtschaft.tu-chemnitz.de

Professorship Management Accounting and Controlling

Prof. Welf-Guntram Drossel

Professorship for Machine Tools and Forming Technologyphone: +49 (0)371 531-23500

fax: +49 (0)371 531-23509

e-mail: wzm@tu-chemnitz.de

Professorship for Machine Tools and Forming Technology

Ronny Sygulla

Professorship Management Accounting and Controllingphone: +49 (0)371 531-37947

fax: +49 (0)371 531-837947

e-mail: ronny.sygulla@wirtschaft.tu-chemnitz.de

Professorship Management Accounting and Controlling

CWG2:

Prof. Egon Müller

Professorship of Factory Planning and Factory Managementphone: +49 (0)371 531-35309

fax: +49 (0)371 531-23229

e-mail: egon.mueller@mb.tu-chemnitz.de

Professorship of Factory Planning and Factory Management

Prof. Matthias Putz

Fraunhofer IWUphone: +49 (0)371 5397-1349

fax: +49 (0)371 5397-61349

e-mail: matthias.putz@iwu.fraunhofer.de

Fraunhofer IWU

CWG3:

Prof. Arnd Meyer

Professorship of Numerical Mathematics (Numerical Analysis)phone: +49 (0)371 531-22520

fax: +49 (0)371 531-22509

e-mail: arnd.meyer@mathematik.tu-chemnitz.de

Professorship of Numerical Mathematics (Numerical Analysis)

Dr. Volker Wittstock

Profesship for Machine Tools and Forming Technologyphone: +49 (0)371 531-37822

fax: +49 (0)371 531-837822

e-mail: volker.wittstock@mb.tu-chemnitz.de

Professorship for Machine Tools and Forming Technology

CWG4:

Prof. Andreas Schubert

Professorship Micromanufacturing Technologyphone: +49 (0)371 531-34580

fax: +49 (0)371 531-23549

e-mail: andreas.schubert@mb.tu-chemnitz.de

Professorship Micromanufacturing Technology

Prof. Klaus Nendel

Professorship of Materials Handling and Conveying Engineeringphone: +49 (0)371 531-32323

fax: +49 (0)371 531-23119

e-Mail: klaus.nendel@mb.tu-chemnitz.de

Professorship of Materials Handling and Conveying Engineering

CWG5:

Prof. Reimund Neugebauer

President of Fraunhofer-Gesellschaftphone: +49 (0)89 1205-1000

fax: +49 (0)89 1205-771000

President of Fraunhofer-Gesellschaft

Prof. Bernhard Wielage

Professorship of Composite Materialsphone: +49 (0)371 531-36169

fax: +49 (0)371 531-23819

e-mail: bernhard.wielage@mb.tu-chemnitz.de

Professorship of Composite Materials

Frank Schieck

Fraunhofer Institute for Machine Tools and Forming Technology IWUphone: +49 (0)371 5397-0

fax: +49 (0)371 5397-1404

e-mail: info@iwu.fraunhofer.de

Fraunhofer Institute for Machine Tools and Forming Technology IWU